Fully integrated process chains in the aviation & space industry with real-time control and stability

The aerospace industry is growing - driven by more flights, rising passenger numbers and ambitious space projects. This creates a wide range of opportunities to exploit new markets and bring technologies to series maturity. At the same time, requirements for flexibility, process reliability, quality and delivery capability are increasing. Global supply chains, high safety standards and the changing demand for skilled workers require new manufacturing strategies. DMG MORI provides support with integrated process chains, real-time transparency and high stability. This enables complex projects to be implemented efficiently and innovations to be scaled successfully.

Initial Situation

Aviation & Space on the upswing

The demands placed on materials and components are extremely high, especially in the aerospace industry. Components must not only withstand extreme loads, but also offer maximum weight efficiency. This combination of lightness and resilience requires innovative materials, precise manufacturing technologies and specialized processing strategies. This is precisely why it is crucial to rely on experienced partners who are not only technological leaders, but also have a deep understanding of the industry-specific requirements. DMG MORI offers a comprehensive portfolio of machines, automation solutions and digital services - combined with decades of experience in aerospace manufacturing.

Although the aviation & space industry is booming, it continues to face major challenges. A key difficulty for manufacturing companies is finding sufficient capacity at suppliers. Partners who can not only meet the necessary certifications and quality standards, but are also able to deliver the most demanding parts and components in the required quantities on time.

The industry is also susceptible to unforeseen events such as raw material shortages, supplier failures or sudden fluctuations in market demand. Companies must therefore be able to adapt their production quickly to avoid downtime. This requires robust and resilient supply chains that can absorb disruptions. In addition, the global nature of supply chains in Aviation & Space complicates the logistical effort.

In addition, competitive pressure is forcing companies to continuously invest in future-proof technologies. The adaptation of production methods, the integration of digital solutions and the development of innovative products often represent a considerable financial burden.

DMG MORI supports companies as an experienced partner in all phases of production: from the feasibility analysis and economic feasibility studies to the installation of the machines, including customized application technology and a comprehensive after-sales service. We are the leading partner for the aviation & space industry: "Such partnerships are already essential in production, where a large proportion of investments are made," says Michael Kirbach. The cooperation with aircraft and engine manufacturers makes aviation an undisputed focus sector for DMG MORI.

Quality and safety first and foremost

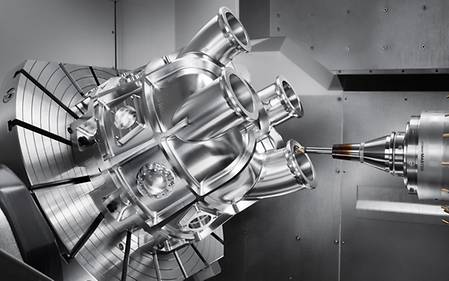

The aviation & space industry is regarded as a driving force for technological excellence. Requirements for precision, quality and safety set standards - not only within the sector, but also for many other branches of industry. Materials and components must be able to withstand extreme loads and at the same time meet the highest lightweight construction requirements, which is reflected in high safety standards, comprehensive quality controls and a zero-defect tolerance. For aerospace certifications and approvals, each production step also requires comprehensive documentation and complete traceability of the components in the supply chain. "Certifications such as AS9100 for the production of new aviation components ensure the highest quality standards. In addition, the requirements for high cost-effectiveness are enormous because small batch sizes with high variance dominate," says Kirbach.

In addition, manufacturers aim to further develop spacecraft and aircraft, their propulsion systems and satellites in order to further reduce energy consumption and emissions. These projects are likely to become increasingly important in the industry, which can be described as a driving force, in the coming years and will be guided by legal regulations.

High demands on production

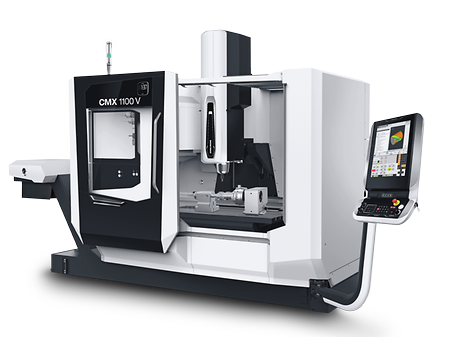

Due to the need to produce small to medium quantities, often with high variance, the demands on production are high. Very flexible systems are usually used: On the one hand, stable machines with high-torque spindles for difficult-to-machine materials such as titanium and nickel alloys, and on the other, dynamic machines with powerful and fast spindles for easy-to-machine materials or aluminum alloys. The combination of the respective material and often complex geometries, for example with low wall thicknesses, can pose many material-specific challenges, such as distortion due to residual stresses.

Value Added

Technology drivers in the aviation & space industry

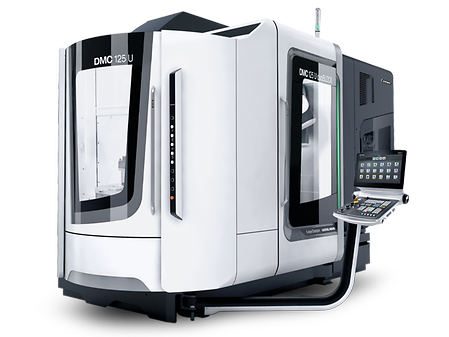

DMG MORI offers companies in the Aviation & Space sector a wide range of customized solutions tailored to the high standards and requirements of the industry. Our range includes high-precision machine tools specifically designed for the machining of complex components. They are ideal for processing materials such as titanium, aluminum and composite materials, which are preferred in the airframe due to their lightness and strength. The same applies to the machining of Ni-based alloys, which withstand the high mechanical and, above all, thermal loads in the engines. DMG MORI also offers comprehensive process solutions that increase production efficiency. This includes the integration of modern CAD/CAM systems and advanced automation solutions that optimize the production process and make it more efficient.

"We only use the highest quality steel, titanium and aluminum alloys," explain Thomas Heinrich and Steffen Rössner, both responsible for programming in mechanical production at Airbus Helicopters, a long-standing customer of DMG MORI. As these are exclusively safety-relevant workpieces, machining is carried out in frozen processes. "This means that once components and their manufacturing processes have been certified, nothing can be changed - neither programs nor tools."

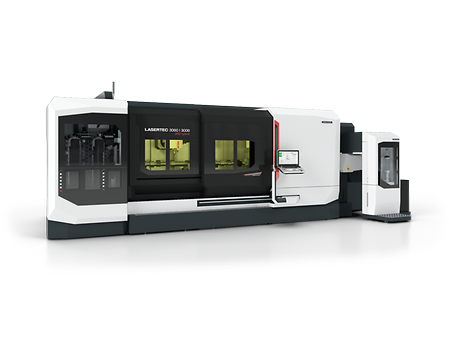

An important part of our offering is additive manufacturing: DMG MORI's innovative approach to hybrid machining combines conventional manufacturing processes with 3D printing processes, which can be used to make product development more flexible and creative. We offer our customers digital solutions that enable comprehensive networking and real-time monitoring of production processes. With IoT technologies and data-based analysis, companies can increase their efficiency and reduce maintenance costs at the same time. Our portfolio is complemented by excellent global service and support, which ensures that machines are always ready for use and production downtime is minimized. This holistic offering from a single source makes DMG MORI a leading partner for the Aviation & Space sector.

"The combination of laser deposition welding and 5-axis simultaneous milling on the LASERTEC 65 DED hybrid has sustainably optimized our processes in prototype construction," believes Takuya Honda, Plant Manager at AeroEdge Co, Ltd. The company, which manufactures prototypes and series parts for customers in the aerospace industry, sees additive manufacturing as a key technology for the future - and relies on DMG MORI for this.

Your advantages as a customer of DMG MORI

As a DMG MORI customer, you benefit from our many years of experience in the Aviation & Space sector. Our complete solutions include premium machines such as the duoBLOCK series (e.g. DMU 80 P duoBLOCK, DMC 125 FD duoBLOCK), which is ideal for machining complex geometries such as engine housings, landing gear and structural components, which are frequently found in the aviation industry. The CTX series, such as the CTX gamma 1250 TC, offers high-precision turning and is designed for machining rotationally symmetrical parts such as shafts and ring-shaped engine components. Thanks to maximum precision and flexibility, machines such as the monoBLOCK series or larger portal machines are also ideal for the production of small to very large structural components and other demanding parts. In addition to the machine products, we offer customized machine options that are essential for customers depending on the process or specification, as well as all associated process and software solutions.

DMG MORI customers also receive a wide range of services: Our comprehensive service and support services as well as our presence in over 40 countries worldwide ensures that companies can always make optimum use of their machines.