gearBROACHING

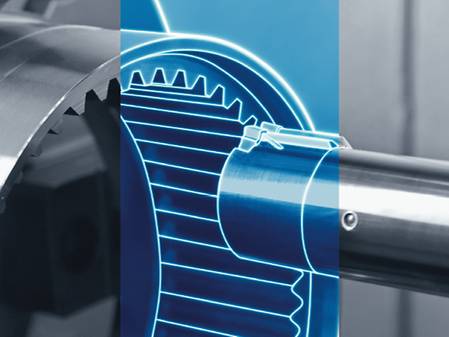

POSITION-ORIENTED MACHINING OF GEARS AT THE MAIN AND COUNTER SPINDLES

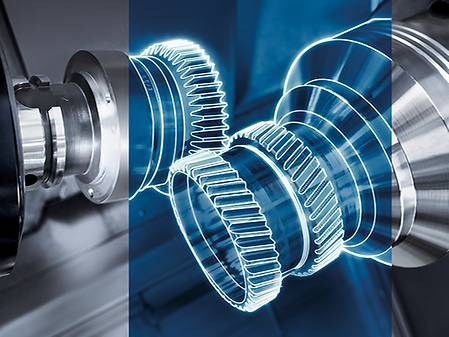

- Internal and external gears

- Ideal for workpieces with shoulders or interference contours due to runout

- Compensation parameters for deflection of the tool holder

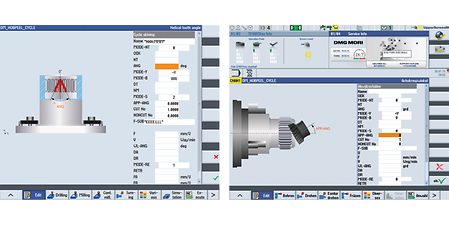

- Available for machines with SIEMENS / CELOS with SIEMENS

GEAR-CUTTING - WE HAVE THE SOLUTION

Check also gearSKIVING and gearMill

Overview

NTX 1000 /

CTX beta TC (4A)

NTX 3000 /

CTX gamma TC

≤ 2

≤ 4

≥ 9

≥ 9

max. 500 mm

max. 670 mm /

max. 700 mm

* Depending on machine & technology

** Depending on internal or external gear teeth as well as tool dimensions and machine size

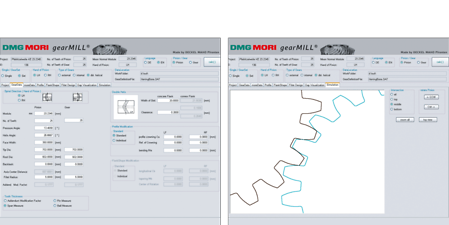

TECHNOLOGY CYCLES

- Straight and helical external or internal spur gears and splines

- Arrow teeth with tooth offset Turn-mill machines

- Ball-shaped toothing by mathematical transformation of the 6th virtual axis

- Productive complete processing

- Cost-effective gear cutting on standard machine with standard tools

- Flexible for different gear geometries

- Quality inspection in the process

- Program creation based on blank drawings and gear data

- Optimization of workpiece orientation e.g. after heat treatment

- Interface for coordinate measuring device (Klingenberg, Leitz, Zeiss)

- Broaching of internal and external splines with dialogue guided programming

- One-Tooth up to 4-theeth cutting tools with clear tool definition for easy setup.

- Compensation parameters for tool holder deviation in X-direction

- Fast process setup with safer programming

- High flexibility while process adaption and corrections

- Internal and external gears up to module 4*

* on CTX beta TC up to Module 2 I on CTX gamma TC up to Module 4 I depending on workpiece and cutting tool dimensions

CUSTOMER VOICES & VIDEOS

Special technical articles, analyses and background information on topics that move our industry.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://mydmgmori.com/

Thank you very much for your interest.

Please fill out the form below to download the requested document.

If you accept the storage of cookies, this form appears only once during your visit.