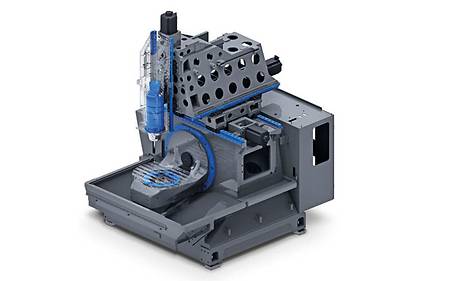

ULTRASONIC 50

Your perfect entry into 5-axis ULTRASONIC machining

Max. X-axis stroke

26 in.

650 mm

Max. Y-axis stroke

20 in.

520 mm

Max. Z-axis stroke

19 in.

475 mm

Max. workpiece diameter

25 in.

630 mm

Max. workpiece height

20 in.

500 mm

Max. workpiece weight

661 lbs.

300 kg

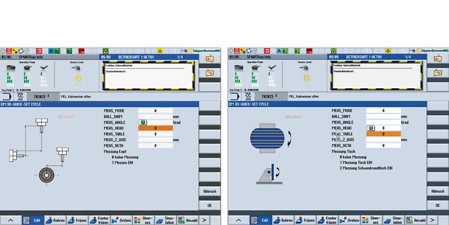

Control & software alternatives

SIEMENS

Highlights

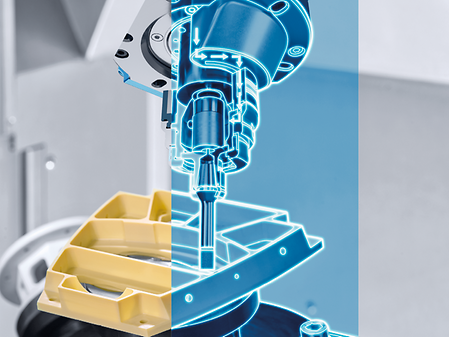

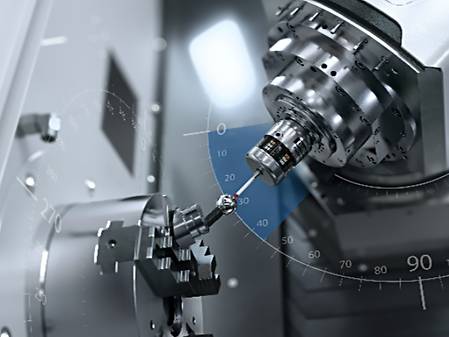

ULTRASONIC technology integration - reduced process forces for higher productivity

- Technology integration via HSK-A63 interface for ultrasonic superimposition of the tool rotation with amplitudes up to 15 µm

- Process forces reduced by up to 50% through ULTRASONIC enable, depending on requirements: higher feed rates, improved surface quality up to Ra <0.1 µm, longer tool life

- Specific coolant treatment systems with centrifuges, optimized for the ULTRASONIC processing of Advanced Materials

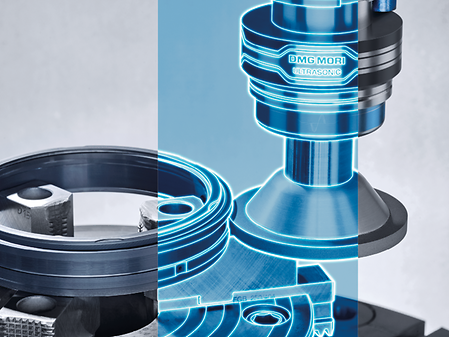

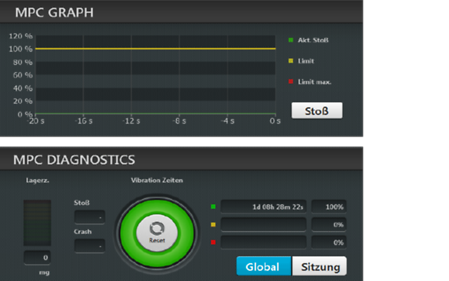

ULTRASONIC 3rd Generation - Optimal process control through intelligent controls

- Constant amplitude in the process to ensure reproducibility

- Automatic detection of the working frequency, significantly improved hardware for signal acquisition

- Frequency tracking and simultaneous power control in real time for optimal process stability

- Ensuring the ULTRASONIC advantages even with non-optimal tools

- Fully compatible with 2nd generation ULTRASONIC actuator

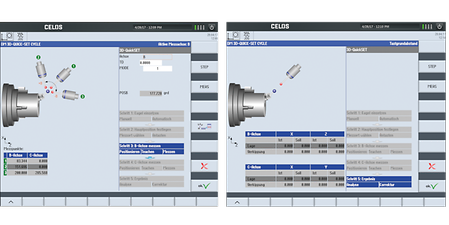

The right machine configuration for every requirement, from 3-axis to 5-axis simultaneously

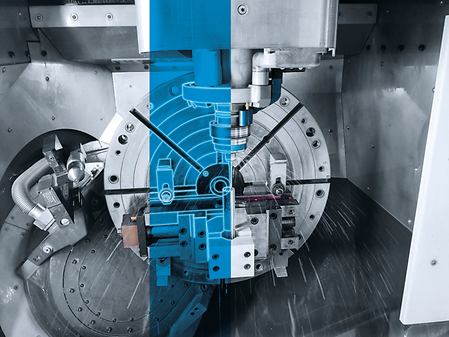

- Attractive 3-axis entry-level machine for ULTRASONIC machining - rigid table with 630 mm x 500 mm clamping surface and a maximum workpiece weight of 300 kg

- Direct-Drive C-axis up to 300 rpm, with 4-channel rotary feedthrough for vacuum - the perfect machine for processing rings made of ceramic and quartz glass

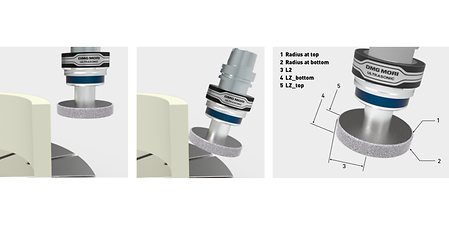

- Adaptive auxiliary spindle ULTRASONIC microDRILL with up to 32,000 rpm for small bores from Ø 0.1 mm with maximum process reliability

5-Axes Machining with up to 20,000 rpm

- speedMASTER 15,000 rpm with 21kW and 111Nm in basic version

- speedMASTER 15,000 rpm with 46kW and 200Nm optionally available

- speedMASTER 20,000 rpm with 35kW and 130Nm optionally available

Swivel Rotary Table for 5-Axes Simultaneous Machining

- Table load up to 300 kg

- Swivel area of the B-axis -35°/+ 110° for highest flexibility

- Cooled table bearings for highest precision

Tool magazine with 30 pockets in basic version

- Loading of tools from the front even during machining

- Excellent visibility and accessibility

- 60 or 120 pockets optionally available

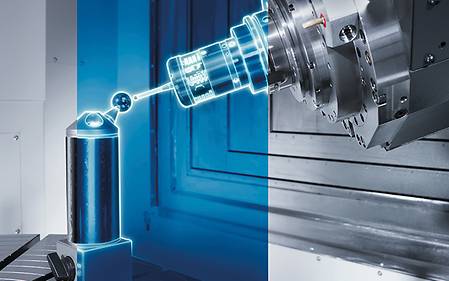

Precision

- Comprehensive cooling concept for highest longterm precision

- One-piece machine bed

- Direct driven ball screw drives

- Direct path measuring systems in all axes

Application Examples

Automation

Standard automation and customized solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customized automation solution for flexible manufacturing systems: