ULTRASONIC: Innovative ultrasonic machining for hard and brittle materials

Short processing times, high productivity and accuracy for the production and machining of brittle and hard materials (advanced materials), such as ceramics, glass, corundum, carbide and fibre-reinforced materials (composites): all of this is now possible with ultrasound-assisted grinding, milling and drilling using machines from DMG MORI’s ULTRASONIC series.

Top-Seller

ULTRASONIC Machining: Advantages of ultrasonic technology

Superimposing a longitudinal ultrasonic vibration on the rotating tool reduces the process forces by up to 50 percent during machining. Depending on the requirements, this could make it possible to increase feed rates, improve surface quality, minimise wear and tear of the tool and consequently achieve the production of high-precision materials. Microscopic cracks inside the material (also referred to as SSD or sub-surface damages) are reduced to a minimum, which significantly shortens the time required for subsequent polishing processes.

All of these properties make ultrasonic technology a highly productive and reliable method that is particularly well suited for the production of components in the optics and semiconductor industries. Whether you need 5-axis grinding of ceramics, drilling of glass, insertion of micro-holes in workpieces or a combination of all of these – the ULTRASONIC series offers the right machine for every application.

Overview

Series with the highest quality in ultrasonic machining

With the ULTASONIC series, DMG MORI has created a range of innovative solutions for grinding, drilling, milling and mill-turning, which, in combination with ultrasonic machining, are capable of handling even the most demanding materials. The users of DMG MORI machines benefit not only from excellent component quality, but above all from enhanced process reliability and an extended service life.

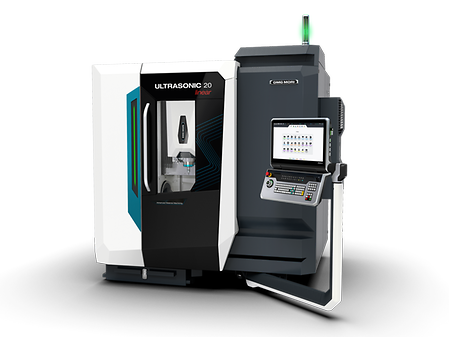

ULTRASONIC Precision

In the new ULTRASONIC Precision series, DMG MORI combines ULTRASONIC technology with the highlights of flexible and high-precision machine tools, making them the benchmark for the efficient machining of hard-brittle materials such as ceramics, glass and Zerodur. The machines of the ULTRASONIC Precision series represent a completely revised and further developed machine generation. FEM-optimized casting beds, wider guides and holistically optimized temperature management guarantee the highest machine and component accuracy over the entire life cycle of the machines.

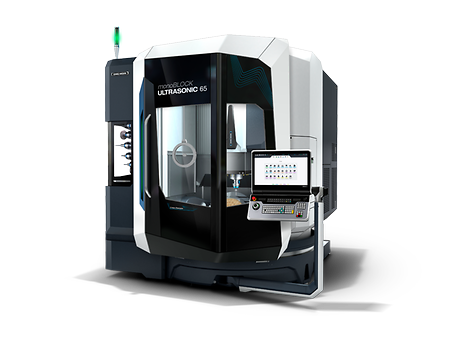

ULTRASONIC Universal

The ULTRASONIC Universal machines from DMG MORI are long-established machine concepts from the conventional machining sector, with integrated ultrasonic technology. A wide variety of industries use the ULTRASONIC models, from 5-axis simultaneous milling to milling-turning with up to 1,200 min-1 table speed to power machining with up to 430 Nm of torque. The following applies to all processes: ULTRASONIC machining turns every machined component into a masterpiece. The ULTRASONIC machining centers stand for a high variety of machining from highly dynamic 5-axis simultaneous machining to milling-turning machining. Large travel distances of up to 6,000 mm and a high table load of up to 25 tons can be realized, as well as numerous automation systems specialized in the machine concepts for set-up parallel to production time for maximum productivity in production.

ULTRASONIC Production

The machines of the ULTRASONIC Production series impress with their optimal symbiosis of precision and cost-effectiveness. They are the measure of all things when it is not a matter of the last μm, but the focus is on the process-reliable and repeatable processing of hard-brittle materials. ULTRASONIC Production machines enable the optimal and cost-effective entry into ULTRASONIC machining.

Important questions about ultrasonic technology

How does ultrasonic machining work?

An ultrasonic generator produces high-frequency alternating voltage, which is transferred without physical contact to the rotating tool holder – also referred to as an actuator – using patented inductive energy transmission. Piezo elements in the actuator convert the alternating voltage into mechanical ultrasound oscillation. The vibration that is generated in this way is transferred to the tool.

The ultrasonic generator is operated with intelligent control algorithms to ensure that the optimal process parameters are maintained at all times during the machining process. Depending on the type of machining, the tool may oscillate up to 65,000 times per second with an amplitude of up to 15µm. This enables the tool to remove even the smallest particles from the surface of the material. At the same time, the diamond tool removes the removed material with additional rotation.

What strategies and processes are used?

The perfect machining strategy is developed specifically for each material and each machining task and can be implemented easily through selected ULTRASONIC cycles. Based on a HSKE32 / HSK-E 40 / HSK-A63 / HSK-A100 tool holder, the patented ULTRASONIC actuator system can be integrated flexibly into almost all 5-axis milling machines from DMG MORI.

The machine concepts range from standard 3-axis machining to 4-axis and 5-axis simultaneous machining. Optional high-speed direct-drive C-axes and mill-turn packages provide additional machining capabilities, e.g., for external cylindrical grinding / internal cylindrical grinding of hard/brittle advanced materials.

What is the difference from ultrasonic vibration lapping?

Ultrasonic vibration lapping is a highly precise metal-cutting manufacturing technique. According to the DIN 8589 standard, ultrasonic vibration lapping is classified as lapping. Unlike other lapping processes, however, it is only used for drilling and cutting. The tool vibrates at ultrasonic frequency in the longitudinal direction. Unlike ultrasonic machining with machines from the ULTRASONIC series, the diamond grain is not on the tool, but in the lapping material.