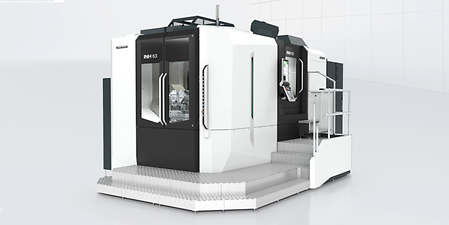

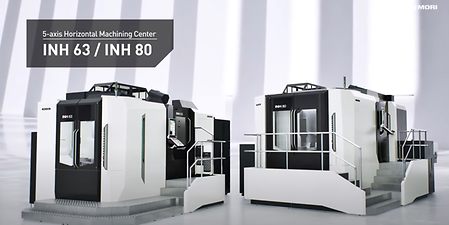

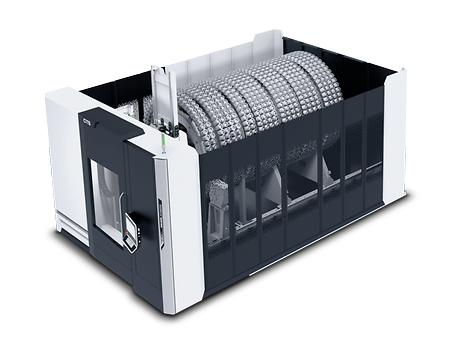

INH 63

Precision, productivity and flexibility in compact body

Max. X-axis stroke

41 in.

1,050 mm

Max. Y-axis stroke

43 in.

1,100 mm

Max. Z-axis stroke

41 in.

1,050 mm

Max. workpiece diameter

42 in.

1,070 mm

Max. workpiece height

39 in.

1,000 mm

Max. workpiece weight

2,205 lbs.

1,000 kg

Control & software alternatives

MAPPS Fanuc

Highlights

Machine structure with twin ball screws for X, Y, Z and slanted column

Large working area

- X / Y / Z-axis travel: 1,050 / 1,100 / 1,050 mm, 630 × 630 mm pallet size

- Workpieces 5-axis up to ø 1,070 × 1,000 mm / 1,000 kg

(ø 1,070 × 1,300 mm / 1,500 kg for machining without A-axis functionality possible)

36 month warranty with unlimited spindle hours

- powerMASTER spindle with 12,000 rpm, 808 Nm and 85 kW (10 %) as standard. 549Nm (High-Speed) and 1,414Nm (High Torque) available as options

Highly rigid & dynamic design

- Twin ball screws for X, Y, Z and slanted column

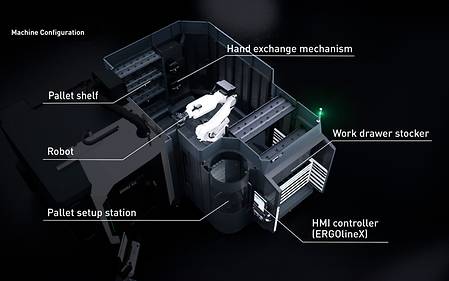

LPP-pallet handling, high productivity pallet storage solution

- Up to 99 pallets

- Operated via machine HMI or via the DMG MORI master

- LPS 4 is equipped as standard

- MCC-TMS is equipped as option

Workpiece handling

- Robot system MATRIS. no programming required

In-Machine Coolant (standard)

- Hybrid cleaning method to avoidchip accumulation

- Fixed outlets on ceiling, sides and spindle nose

- Controlled ceiling nozzles direct the coolant specifically to the areas,where chips can accumulate

- New: 2 frequency-controlled high-efficiency pumps with control valves for the high- and low-pressure range

Application Examples

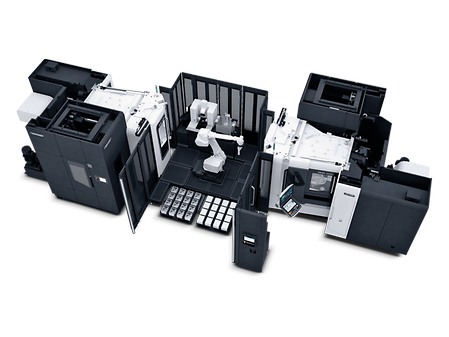

Automation

Standard automation and customized solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customized automation solution for flexible manufacturing systems: