AMR 2000

Holistic automation on the shop floor

- Collaborative automation solution with free layout design

- Omnidirectional movement for minimal space requirements (turning radius 0m)

- Basis for additional tasks, e.g. B. tool handling, chip disposal, etc.

- Material transport from Euro pallets 1,200 x 800 mm

- Maximum transport weight of up to 2,000 kg

- Security based on Sick and Siemens technology

Highlights

AMR 2000 Material

- Autonomous transport of material pallets

- Transport of different load carriers

- Integration into DMG MORI automation systems for workpiece handling – exchange of finished part and raw part pallets

- Integration into existing processes

- Scalable and expandable at a later date

AMR 2000 chips

- Autonomous transport of chip containers

- Automatic transport order from the master computer

- Extended autonomy of the machine tool

- Material and chip transport can be combined

AMR 2000 tool handling

- Tool identification in the standard

- Autonomous transport and exchange of tools between machines and tool storage systems

- Max. tool dimensions ø 280 / 400 mm

- Max. tool weight 30 kg

- Transport weight 720 kg (24× 30 kg)

- Maximum number of tools: 24 pcs

Videos

Technical data

AMR 2000

Max. loading

Navigation

Length

Width

Height

Max. speed

Max. running time

(without recharging)

(without recharging)

Position accuracy

Loading time from 0 to 100 %

Max. gradient

Drive concept

Charging technique

Standard communication interface

Vertical lifting axes

Max. tool weight

Max. tool number

Tool taper

Max. tool dimension

Chips / Material

2,000 kg

Laser

1,480 mm

990 mm

478 mm

6 km/h

8 h

free ±10 mm

2 h

7%

Omnidirectional

Inductive

VDA 5050

yes

Tool handling

900 kg

Laser

1,480 mm

990 mm

2,400 mm

6 km/h

8 h

free ±10 mm

2 h

7%

Omnidirectional

Inductive

VDA 5050

no

30

24

SK 40 /50

HSK-A63 / 100

HSK-A63 / 100

⌀ 280 * 650

Machine

CLX 350

CLX 450

CLX 550

CLX 750

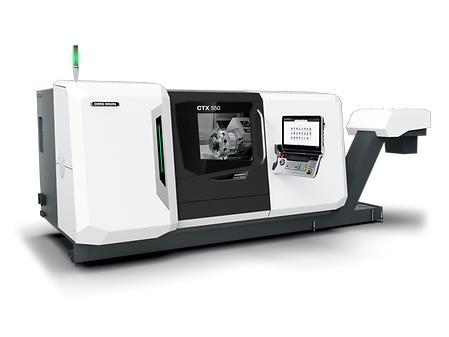

CTX 350

CTX 350 4A

CTX 450

CTX 550

CTX alpha 500

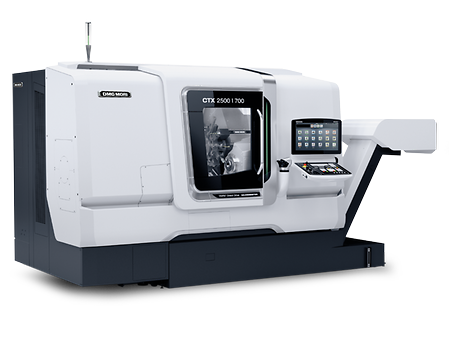

CTX 2500

CTX beta 800

CTX beta 2000

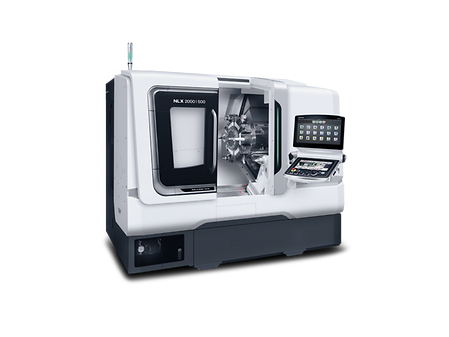

NLX 1500

NLX 2000

NLX 2500

NLX 2500 | 750 2nd Gen.

NLX 3000

NLX 4000

NLX 6000

CLX 450 TC

CLX 550 TC

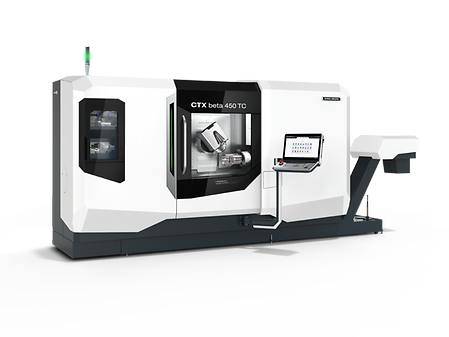

CTX beta 450 TC

CTX beta 800 TC

CTX beta 1250 TC

CTX beta 1250 TC 4A

CTX beta 2000 TC

CTX gamma 1250 TC

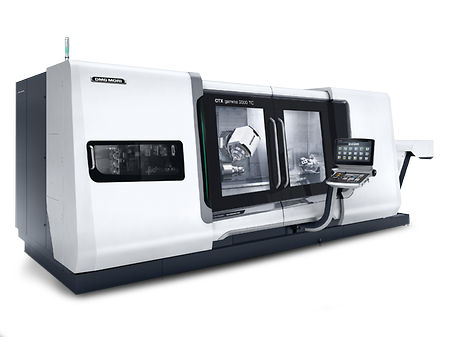

CTX gamma 2000 TC

CTX gamma 3000 TC

NTX 500

NTX 1000

NTX 2000

NTX 2500

NTX 3000

NT 4200 DCG

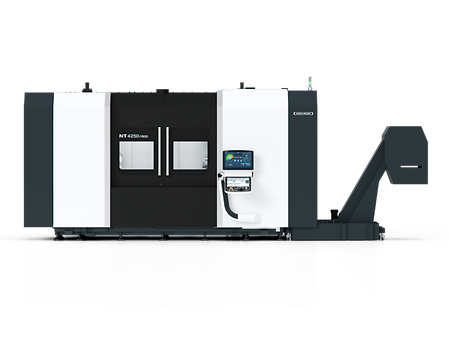

NT 4250 DCG

NT 4300 DCG

NT 5400 DCG

NT 6600 DCG

WASINO G-06

WASINO G-07

WASINO G 100

WASINO GG-5

WASINO A-18S

WASINO AA-1

WASINO J-1

WASINO JJ-1

NZX-S 1500

NZX-S 2500

ALX 1500

ALX 2000

ALX 2500

NRX 2000

NZ DUE

NZ TRE

NZ QUATTRO

NZX 1500

NZX 2000

NZX 2500

NZX 4000

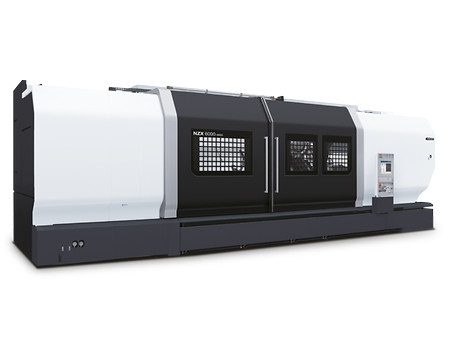

NZX 6000

CTX beta 800 4A

CTX beta 1250 4A

CMX 600 V

CMX 800 V

CMX 1100 V

DMV 115

DMV 145

DMV 185

DMC 650 V

DMC 850 V

NVX 5060 2nd Gen.

NVX 5080 2nd Gen.

NVX 5100 2nd Gen.

NVX 7000 2nd Gen.

i30 V

DMP 35

DMP 70

INH 63

INH 80

NHX 4000

NHX 4000 4. Gen.

NHX 5000

NHX 5000 4. Gen.

NHX 5500

NHX 6300

NHX 8000

NHX 10000

NH 4000

NH 5000

NH 6300

i50 V

NHC 4000*

NHC 5000*

NHC 5500*

NHC 6300*

NHC 8000*

DMU 65 H monoBLOCK

DMU 85 H monoBLOCK

DMC 65 H monoBLOCK

DMC 85 H monoBLOCK

CMX 50 U

CMX 70 U

DMU 50 3rd Gen.

NMV 3000 DCG

NMV 5000 DCG

DMU 65 (FD) monoBLOCK

DMU 65 (FD) monoBLOCK 2. Gen.

DMU 75 monoBLOCK

DMU 75 monoBLOCK 2nd Gen.

DMU 85 (FD) monoBLOCK

DMU 85 (FD) monoBLOCK 2. Gen.

DMU 95 monoBLOCK

DMU 95 monoBLOCK 2nd Gen.

DMU 105 (FD) monoBLOCK

DMU 125 (FD) monoBLOCK

DMC 65 (FD) monoBLOCK

DMC 75 monoBLOCK

DMC 85 (FD) monoBLOCK

DMC 95 monoBLOCK

DMU 40 (FD) eVo

DMU 60 (FD) eVo

DMU 80 (FD) eVo

HSC 20 linear

DMF 200 | 8 (FD)

DMF 300 | 8 / 11 (FD)

DMF 400 | 11 (FD)

DMU 80 P (FD) duoBLOCK

DMU 90 P duoBLOCK

DMU 100 P (FD) duoBLOCK

DMU 125 P (FD) duoBLOCK

DMU 160 P (FD) duoBLOCK

DMC 80 U (FD) duoBLOCK

DMC 90 U duoBLOCK

DMC 100 U (FD) duoBLOCK

DMC 125 U (FD) duoBLOCK

DMC 160 U (FD) duoBLOCK

DMU 200 Gantry

DMU 340 Gantry

DMU 600 Gantry linear

DMU 210 P (FD)

DMU 270 P (FD)

DMU 340 P (FD)

DMU 600 P (FD)

DMC 210 U (FD)

DMC 270 U (FD)

DMC 340 U (FD)

ULTRASONIC 20

ULTRASONIC 50

ULTRASONIC 65 monoBLOCK

ULTRASONIC 85 monoBLOCK

ULTRASONIC 40 eVo

ULTRASONIC 60 eVo

ULTRASONIC 80 eVo

ULTRASONIC 200 Gantry

ULTRASONIC 210 P

ULTRASONIC 55 MicroDrill

AMR 2000

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

AMR 2000 Tool handling

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

●

●

●

●

x

x

x

x

x

●

●

●

●

●

●

●

●

●

●

●

●

●

●

X

X

X

X

X

X

X

●

●

●

●

●

●

●

●

●

●

X

X

X

●*

●*

●*

●*

●*

●*

●*

X

X

X

X

X

X

X

X

X

X

● available

x on request

●* Portal-Mc

* possible in conjunction with pit or TLS