MAPPS X

- DMG MORI specific user interface optimized for vertical screen orientation

- Fully customizable flexible display with up to 10 windows and arrangement in window sets

- 3D collision control and machining simulation

- Comprehensive machining cycles

- Comprehensive machining cycles

- Tool Management System

Highlights

CELOS X software platform

- Standardized app-based user interface independent of the CNC control system

- Possibility of connecting the machine to the company organization

- Application for simple operation, extended spindle hours and increased energy efficiency

- Future-proof thanks to online update options

- Prepared for CELOS Xchange cloud connection

- NETserivce: Remote diagnostics and remote maintenance

- MDC: Standardized machine data output in OPC UA, MT connect and MQ TT formats

- Service Agent: Integrated maintenance manual

ERGOline X operation panel

- 24” multitouch screen with space saving vertical screen orientation

- Full size tactile keyboard

- Two potentiometers for feed and rapid traverse

- Hybrid bar with display buttons for individual button functions

- SMARTkey in credit card format

- Ergonomic angle adjustment

Available Machines

Ultimate Performance for Parts Machining

Ultimate Performance for Parts Machining

Ultimate Performance for Parts Machining

Ultimate Performance for Parts Machining

Elaborate and Dynamic Parts Machining

Large Turning centre Capable of Powerful Machining of Large-diameter Shafts

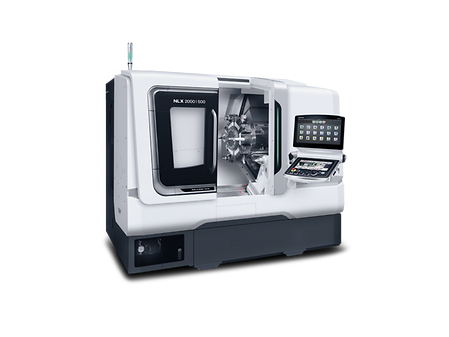

All-round machine for various fields

All-round machine for various fields

All-round machine for various fields

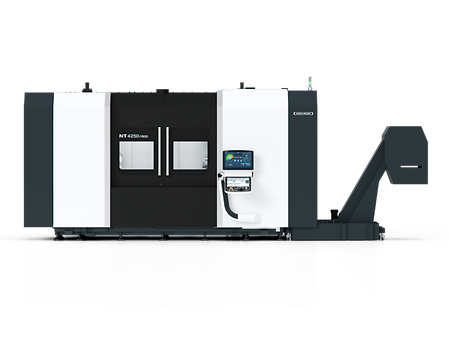

Ultimate Integrated Mill Turn Center

Capable of Handling Long and Large-diameter Workpieces

Covering Extensive Range of Machining Across All Fields

Covering Extensive Range of Machining Across All Fields

6-sided machining with Turn & Mill Spindle compactMASTER

Overwhelming quality by perfect performance

Flat Tooling Turning Centers

High-quality Workpieces Generated by Super-high-precision Machining

Flat Tooling Turning Centers

High-quality Workpieces Generated by Super-high-precision Machining

High-quality Workpieces Generated by Super-high-precision Machining

Flat Tooling Turning Centers

Space-saving 2-spindle 2-turret machine with high functionality and high precision

Best-selling machine featuring high precision and space saving

Ideal for mass-production of flange parts

High-precision Turning Center

2-spindle, 2-turret Turning Center Featuring Y-axis

Professional machine for small diameter shaft machining

Specialist Machine for Shaft Machining with Outstanding Efficiency

Precise Machining of High-performance Mass Production Parts

Four turrets with four 80 mm Y-axes and up to four B-axes.

Three turrets with three 80 mm Y-axes and up to three B-axes. Free positioning of turrets on T1 - T4

Two turrets with two 80 mm Y-axes and up to two B-axes. Free positioning of turrets on T1 - T4

Precise Machining of High-performance Mass Production Parts

Two turrets with two 80 mm Y-axes

Overwhelming Manufacturing Capability Standing Out in Shaft & Flange Machining

Outstanding and Flexible Production Capacity

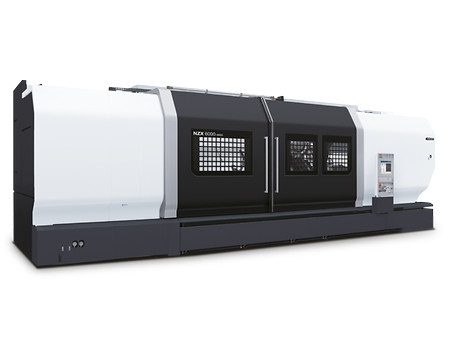

Large-scale high-efficiency 4-axis turning center that achieves the ultimate in productivity with long and large diameter workpieces

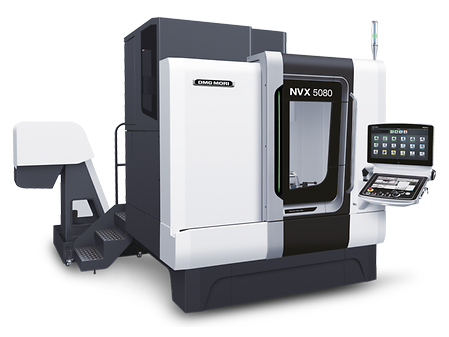

Best-ever high-precision vertical machining center

Best-ever high-precision vertical machining center

Best-ever high-precision vertical machining center

Vertical machining center with large axes travels, suitable for medium and large parts machining

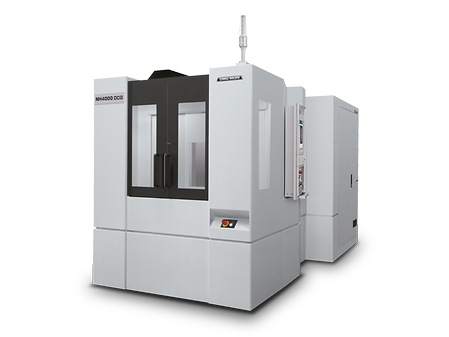

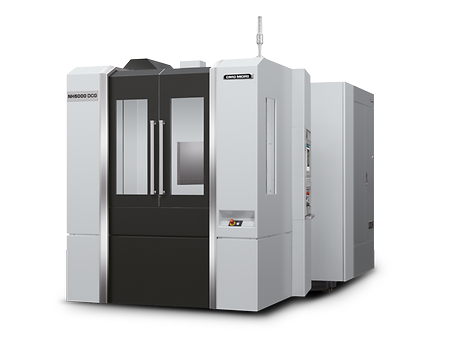

Horizontal machining center with highest stability, precision and dynamics

Horizontal machining center with highest stability, precision and dynamics

Expert on machining of large and difficult-to-cut workpieces

Presenting the ideal machining center

Achieving highest-level speed in the world

Horizontal machining center answering a wide range of requirements from heavy-duty cutting to high-speed cutting

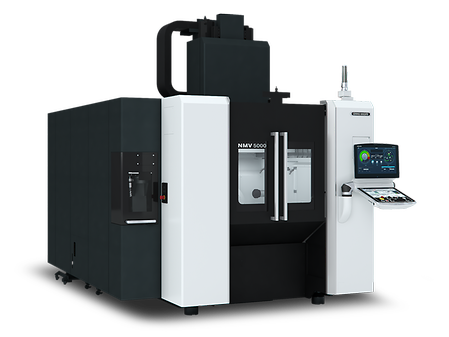

High-precision, 5-axis control vertical machining center that uses DDM on rotary axes

High-precision, 5-axis control vertical machining center

CNC Vertical Multi-Process Grinding Machine

CNC Vertical Multi-Process Grinding Machine

Special technical articles, analyses and background information on topics that move our industry.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Discover exclusive content with your DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Get access to many useful digital functions and services and have all important data at a glance. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

Unlock access to your Share Hub and many other functions and services. With a central DMG MORI Account, you can use all services around the clock from anywhere and with any device.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

- Unlimited product experience – unlock all technical machine data and product brochures.

- Exclusive videos, technical articles, whitepapers and blog articles with deep insights into the DMG MORI product world.

- Personalised access to other DMG MORI Platforms, including Event Platform, Media Library and much more.

Learn more about the DMG MORI Account.

For general enquiries, please use our contact form.

For service and spare parts enquiries please use the my DMG MORI portal: https://mydmgmori.com/

Thank you very much for your interest.

Please fill out the form below to download the requested document.

If you accept the storage of cookies, this form appears only once during your visit.