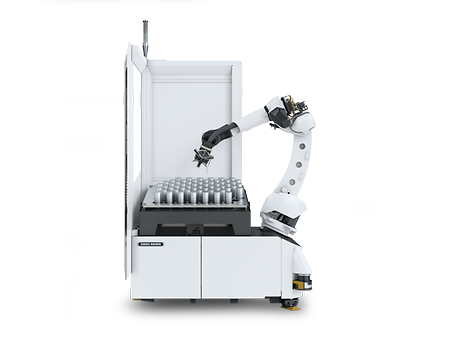

Robo2Go Turning

Flexible workpiece handling for small to medium batch sizes

- One app for uniform control of all Robo2Go variants, setting up a new workpiece < 5 minutes

- Robo2Go Turning, robot payload 12, 25 or 35 kg

- Rapid changeover from chuck to shaft parts

- Robo2Go Vision, robot payload 35 kg

- Robust 3D camera recognition, ideal for multi-job function

Highlights

One app for uniform control of all Robo2Go variants.

- Integrated in the machine control operation via CELOS APP: No need to change your NC programs!

- Intuitive usability thanks to dialog-guided software

- Creation of the process through predefined program modules via drag & drop: No robot programming knowledge necessary

- Setting up a new workpiece < 5 minutes

Robo2Go Turning

- Rapid changeover from chuck to shaft part storage

- Handling of shafts ø 20 – 170 mm and chuck parts ø 20 – 175 mm

- Three versions for all requirements: Robot payload 12 / 25 / 35 kg

- Stacking magazine

Robo2Go Drawer Storage

The storage expantion for your Robo2Go Turning

- 300 % higher capacity compared to standard

- Main time-parallel setup of the workpiece storage

- Multijob per drawer and within a drawer possible in the standard system

- Job management of all jobs via the Robo2Go Jobs app

Robo2Go Vision

- Robust 3D camera recognition, ideal for multijob function

- Infeed and outfeed of raw and finished parts by pallet

- Cylindrical chuck parts of ø 25 – 175 mm

Details

Videos

Technical data

Machine

CLX 350

CLX 450

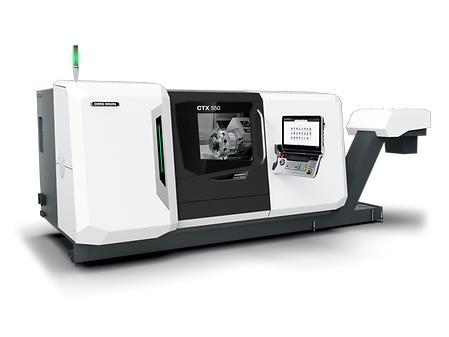

CTX 350

CTX 350 4A

CTX 450

CTX 550

CTX alpha 500

CTX beta 800

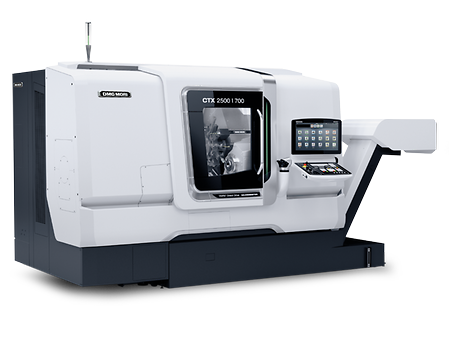

CTX 2500

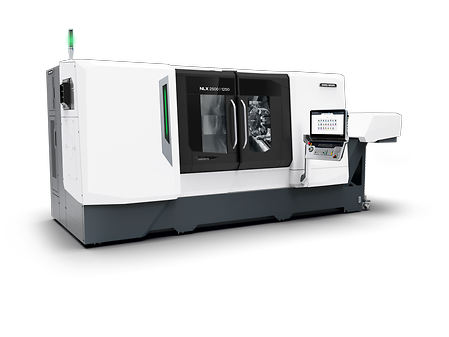

NLX 1500

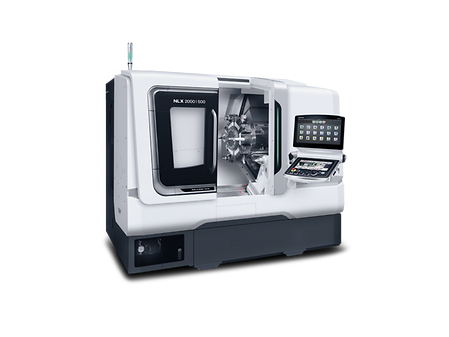

NLX 2000

NLX 2500

NLX 2500 | 750 2nd Gen.

CLX 450 TC

CLX 550 TC

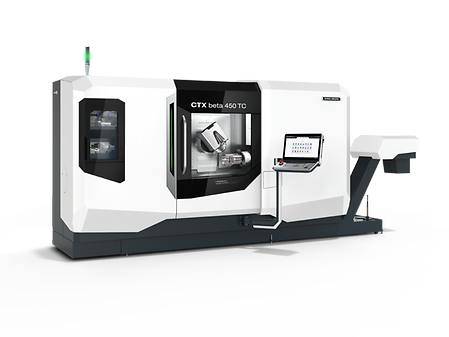

CTX beta 450 TC

CTX beta 800 TC

CTX beta 1250 TC

CTX beta 1250 TC 4A

NTX 1000

NTX 2000

NTX 2500

NTX 3000

NZX 1500

NZX 2000

CTX beta 800 4A

CTX beta 1250 4A

NZ DUE

NZ TRE

NZ QUATTRO

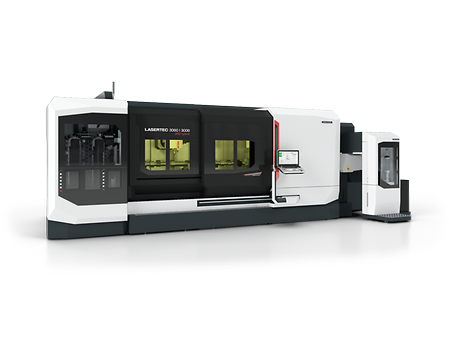

LASERTEC 3000|1500 DED hybrid

12 kg

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

25 kg

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

35 kg

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

Vision 35 kg

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

● available * not available for tuning length 500 mm