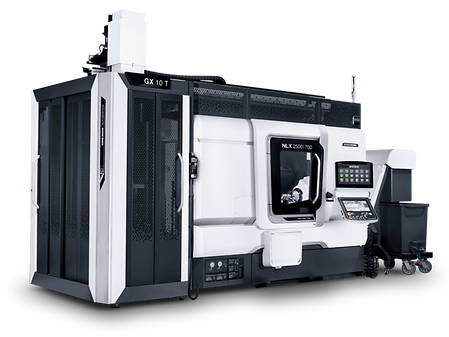

GX / GX T

GX 3 / 5 / 7 / 15 // GX 5 / 10 T - Modular gantry loader system for one or more machines

- Highly productive and flexible workpiece handling for one machine or linking several machines

- GX 10 T: Handling of workpieces up to ø 200 x 150 mm and and weighing up to 10 kg

- Combinable with various kinds of automatic peripheral equipment (washing, measuring, marking, etc.) and grippers of flexible design available

- Easy programming and setup due to integration into the machine control

- Load status monitoring available via DMG MORI Messenger

Highlights

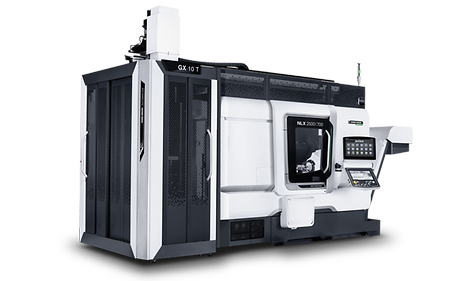

NLX 2500 | 700 with GX 10 T

Highlights GX 3 / GX 5 / GX 7 / GX 15 / GX 5 T / GX 10 T / GX 15 T

- Handling of workpieces up to ø 200 mm, a length of 150 mm and a weight up to 10 kg

- Compact, space saving with built-in loader

- Combinable with various kinds of automatic peripheral equipment (washing, measuring, marking etc.) and grippers available by flexible design

- Easy programming and setup due to integration into the machine control

- Loader status monitoring available via DMG MORI Messenger

- Easily expandable for two or more machines

- Optional up to 100 kg handling weight available

Videos

Technical data

Technical data

Workpiece

Max. workpiece weight kg

Max. workpiece size mm

Capacity

Max. number of pallets

GX 3

2 × 3

ø 150 × 100

14 / 20 / 26

GX 5

2 × 5

ø 150 × 120

14 / 20/ 26

GX 5 T

2 × 5

ø 150 × 120

14 / 20/ 26

GX 7

2 × 7

ø 150 × 120

14 / 20 / 26

GX 10 T

2 × 10

ø 200× 150

10 / 20

GX 15

2 × 15

ø 200 × 150

10 / 20

Machine

NLX 1500

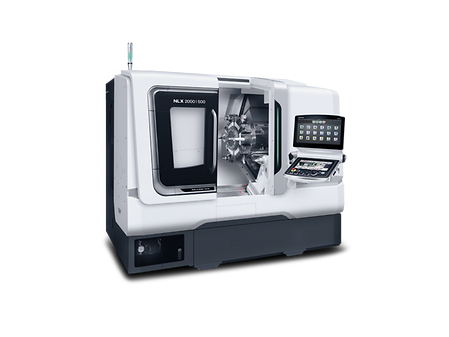

NLX 2000

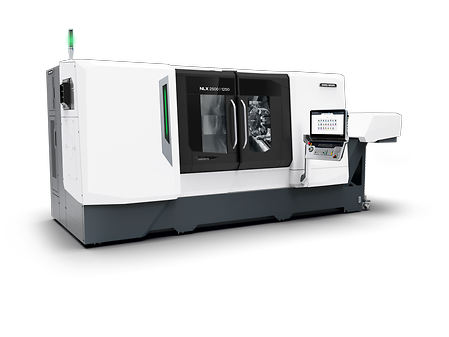

NLX 2500

NTX 1000

NTX 2000

NTX 2500

NTX 3000

NT 4200 DCG

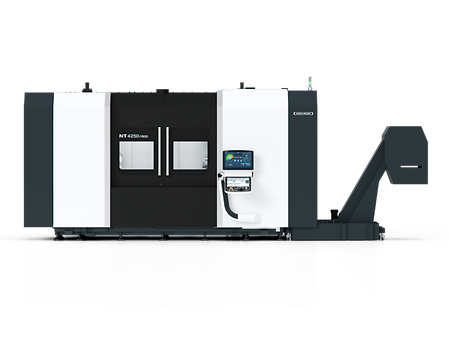

NT 4250 DCG

NT 4300 DCG

NZX-S 1500

NZX-S 2500

ALX 1500

ALX 2000

ALX 2500

NRX 2000

NZ DUE

NZ TRE

NZ QUATTRO

NZX 1500

NZX 2000

NZX 2500

GX 3

●

GX 5

●

●

●

GX 5 T

●

●

●

●

GX 7

●

●

●

GX 10 T

●

●

●

●

●

●

●

●

●

●

●

●

●

●

GX 15

●

●

●

● available