DMG MORI sets new standards in Digital Transformation at EMO

For 50 years, EMO has been regarded as a global barometer for innovation in the machine tool industry. This year, there is a special focus on the future of CNC manufacturing. DMG MORI is paving the way with its Machining Transformation (MX) strategy and its four pillars: Process Integration, Automation, Digital Transformation (DX), and Green Transformation (GX). During EMO, the DX Office and the Shopfloor Hub will present the latest developments and generations of digital solutions to the trade fair audience. The focus will be on technological, economic, and sustainability issues—this time specifically from the perspective of small and medium-sized enterprises in the industry. The challenge of skilled labor shortages will be addressed, as will new ways to achieve greater energy efficiency and meet increasing knowledge and quality requirements.

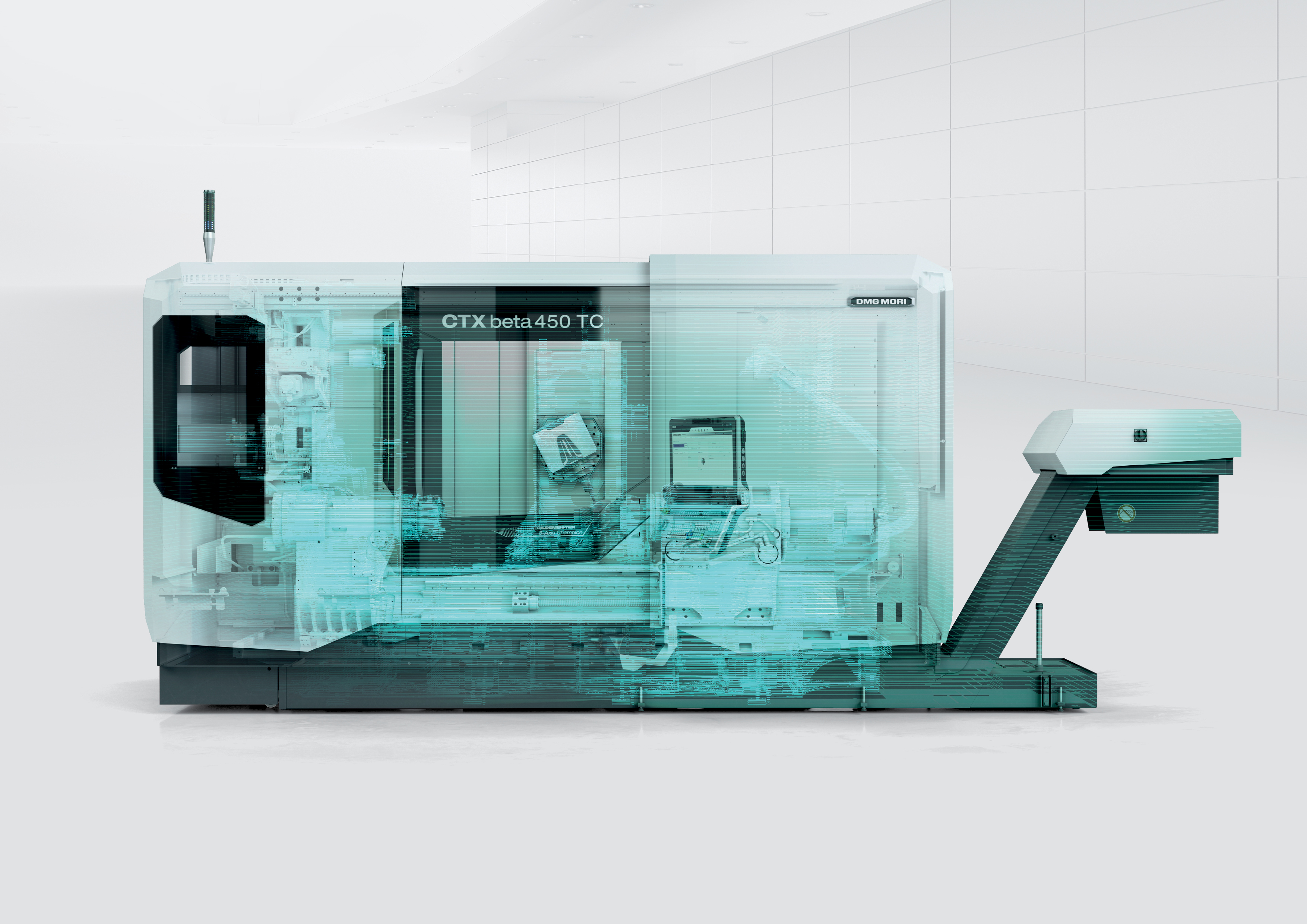

How DMG MORI is digitally redefining CNC manufacturing

CELOS X, GREENMODE, new DMG MORI technology cycles on demand, proprietary CAM add-ons for efficient programming, and the next evolutionary stage of the my DMG MORI customer portal are just a few of the highlights that underscore this claim. Overall, this creates a unique perspective on how digitization can already take ease of use, productivity, and resource efficiency to a new level and become a strategic tool for shaping the future.

CELOS X: The sustainable manufacturing platform

With the latest version of CELOS X, DMG MORI is focusing even more strongly on intuitive operation, simple partner and data integration, energy management, and maximum process reliability overall. Particularly noteworthy is the new Tool Master app, which revolutionizes tool setup with guided work steps and automatic magazine positioning. The optional Tool Data Exchange interface also enables fast data import from presetting devices such as those from HAIMER. The added value is impressive: setup times can be reduced by up to 80 percent, while at the same time reducing the requirements for operator qualification and experience. This means that even less experienced employees can handle complex tasks and help to make processes more effective and efficient.

CELOS X apps for Green Transformation (GX)

The new GREENMODE measures in the CELOS X applications help companies analyze, document, and actively reduce their energy consumption. Three specialized apps form the core of this sustainable solution:

- Energy Monitoring provides detailed energy and CO₂ analyses down to the workpiece level, including cost factors and export functions. This represents an enormous gain in transparency and knowledge with regard to new ESG requirements and the EU's “Ecodesign for Sustainable Products Regulation.”

- Energy Saving enables the intelligent shutdown of machine components in standby mode. At the same time, the integrated warm-up function ensures that machine accuracy is not compromised despite energy savings.

- Air Leakage Monitoring automatically detects compressed air leaks, helping to massively improve the energy balance in CNC manufacturing.

The three CELOX X apps will be available from EMO 2025 for machines with CELOS X and common controls such as Siemens, HEIDENHAIN, and MAPPS.

DMG MORI Technology Cycles on demand – Added value per hour

Technology cycles are only valuable when they are needed. However, some cycles are rarely used. Instead of having to cover every eventuality with a full license, DMG MORI will be offering temporary and flexible activation of selected DMG MORI technology cycles via the my DMG MORI customer portal starting at EMO. Users can thus utilize technology cycles and flexible payment options according to their needs.

my DMG MORI: Digital customer center with self-service solution

The my DMG MORI customer portal acts as a comprehensive digital customer center—from troubleshooting to technology optimization. One of the most significant innovations is self-service: based on error codes, users receive specific instructions for solving problems independently. This functionality not only reduces downtime, but also strengthens users' autonomy in dealing with DMG MORI's high-tech machines.

Digitization as a strategic element for the future

DMG MORI does not view digitization as an additional function, but rather as the foundation of modern CNC manufacturing—and thus as a cornerstone of Machining Transformation (MX). DMG MORI understands that competitiveness in CNC manufacturing is based on the interplay between innovative machines and the ability to continuously improve them and provide software support. Digital access to the machine is therefore fundamental throughout its entire life cycle and represents the real competitive advantage in future-proof CNC manufacturing.