Technological advantage through ultrasonic machining

Modern EUV (extreme ultrasonic lithography) systems produce increasingly powerful microprocessors, as they achieve structure sizes down to a few nanometers, allowing more transistors to be accommodated on small chips. This outstanding technology has its origins in the construction of the lithography systems themselves. To enable them to repeat the same movement and positioning cycles millions of times with atomic precision during wafer exposure and to withstand long-term thermal stresses, their components are made from materials such as silicon carbide and Zerodur. Founded in 1994, Fuchshofer Präzisionstechnik GmbH, located in Eibiswald, Styria, specializes in precise machining of these hard and brittle advanced materials – using ULTRASONIC technology from DMG MORI. The success of ultrasonic-assisted manufacturing is demonstrated by the machining capacity, which includes a total of 14 ULTRASONIC models. Two additional third-generation ULTRASONIC 50 machines were installed in 2024 to meet growing demand from the semiconductor industry.

ULTRASONIC: Machining quality at the highest level

When Fuchshofer purchased its first ULTRASONIC machine from DMG MORI in 2005, the team already had many years of experience in precision machining. Then, as now, the range of services included turning, milling, grinding and wire EDM. “Since 2017, we have also been offering additive manufacturing with Fuchshofer Advanced Manufacturing,” says Aaron Reinisch, referring to the enormous range of manufacture. He heads the Ceramics & Hard Materials division, which primarily includes the ULTRASONIC machines. “Strong growth in the semiconductor industry has led to almost annual investment in this machining technology over the past eight years.” Fuchshofer has remained loyal to DMG MORI's ULTRASONIC models. “We know the machines inside out and they guarantee the high-quality component machining we and our customers expect.”

Ultrasonic-assisted drilling, grinding and 5-axis milling

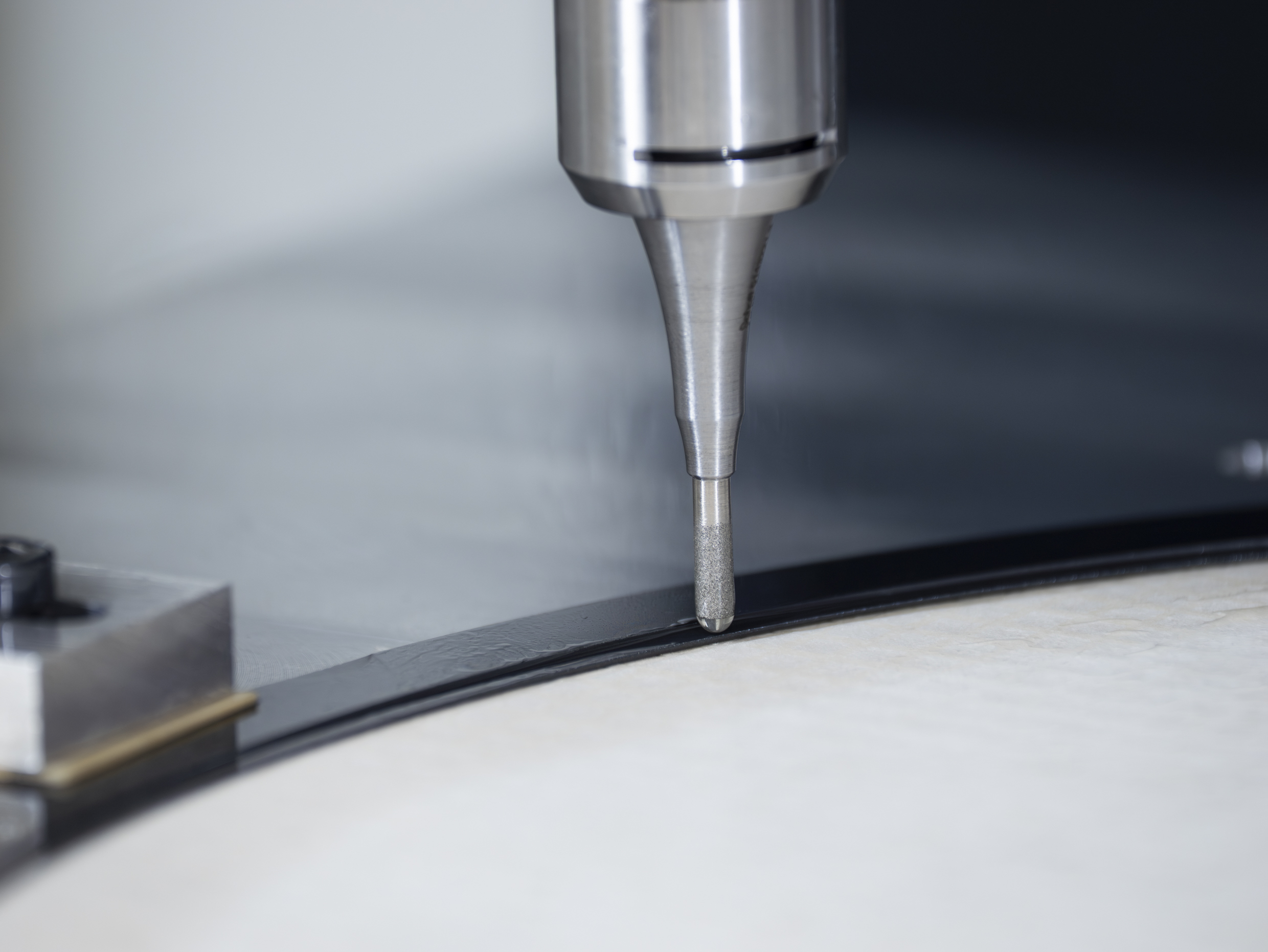

Ultrasonic technology allows Fuchshofer to machine technical ceramics, composites and carbide just as reliably and precisely as quartz glass, Zerodur and sapphire glass. The operating principle is both innovative and simple: an ULTRASONIC actuator causes the tool to vibrate at high frequency, superimposing this oscillation on the rotary and linear motions. It results in pulsating contact between the tool and the workpiece, which among other things enables controlled material removal and minimizes the risk of microcracks.

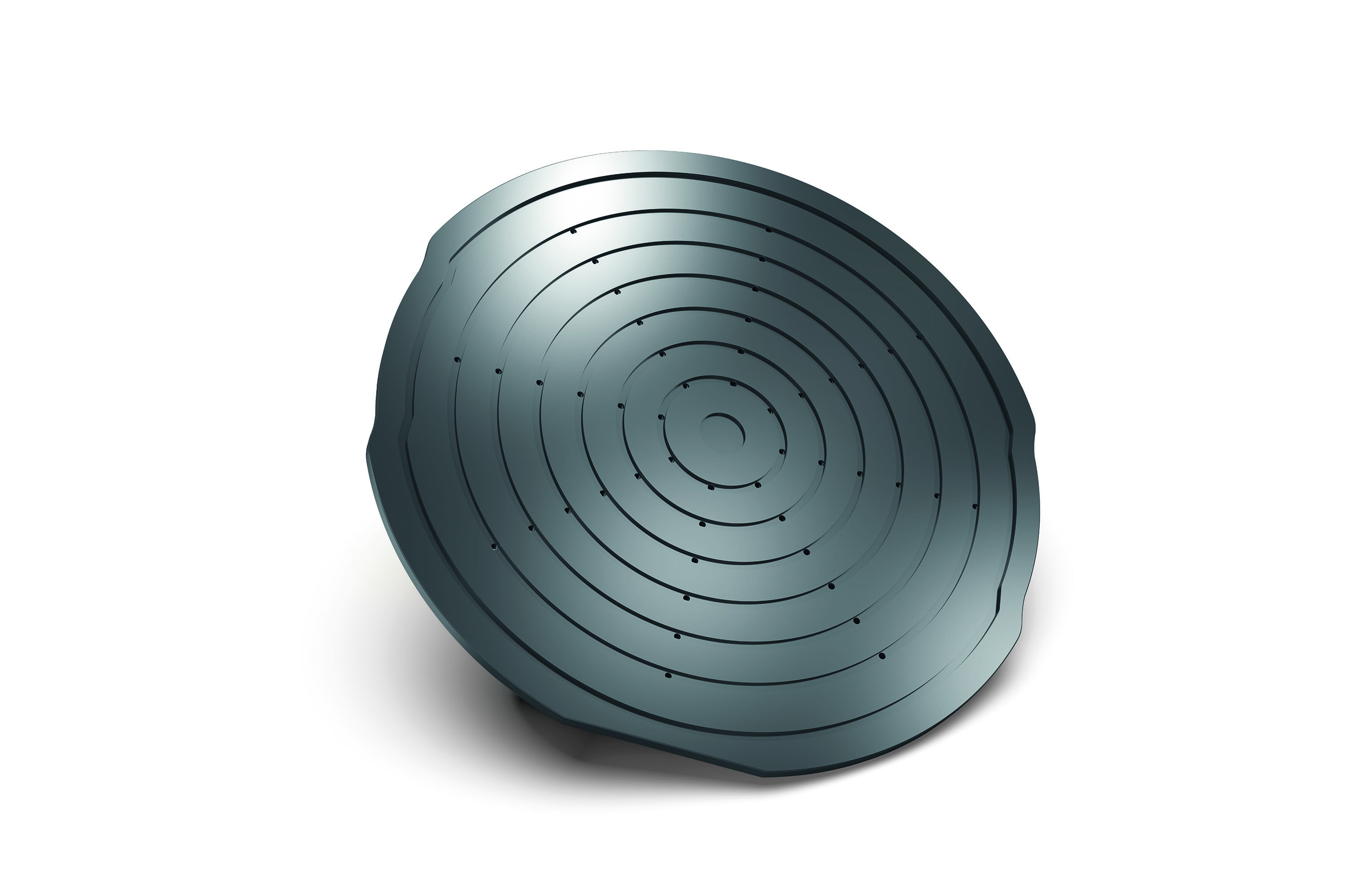

The diverse applications of this technology range from precision drilling down to a diameter of ø 0.4 mm to ultrasonic grinding and 5-axis ultrasonic milling of 3D contours. “Silicon carbide plates currently account for the largest share of our business,” says Aaron Reinisch. The wafers are mounted on them in lithography systems. "As part of the production process of these temperature-stable components, we machine fine cooling channels to make them even more resistant to thermal effects in semiconductor manufacture.

Reliable production with electroplated diamond tools

Since silicon carbide is almost as hard as diamond, ULTRASONIC machining requires appropriate diamond tools. Fuchshofer relies on electroplated grinding pins from Schott and DMQP partner Effgen. “These are self-sharpening tools that have a service life of up to 15 hours and can be dressed three or four times,” says Aaron Reinisch, explaining the choice. It enables highly reliable production with minimal labor. The silicon carbide components are machined according to customer specifications and take up to 60 hours to complete. Aaron Reinisch is completely satisfied: “Scrap rates of less than one percent prove that the process is running optimally.”

Process optimization through close cooperation

The variety of technologies in the factory gives Fuchshofer plenty of scope to develop the best manufacturing strategies. “We work closely with our customers to optimize machining processes,” explains Aaron Reinisch. Sometimes it is more efficient to mill a workpiece on conventional CNC machines, while in other cases an ULTRASONIC machine is absolutely essential. “We always consider the combination of the technical requirements and the advantages of the respective machining process.” Fuchshofer is also venturing into new materials that may become important in the future. Aaron Reinisch cites extremely tough silicon nitride as one example: “The material is very interesting for the semiconductor sector, but extremely difficult to machine.” With the help of ULTRASONIC machines, the team is working on reliable manufacturing solutions for silicon nitride components. “The interaction between the tool, the technology and the cutting parameters is crucial.”

Progressing into new markets

Aaron Reinisch is convinced: “Use of new technologies and optimization of existing processes are key to continuously expanding our range of services.” Fuchshofer's holistic approach and focus on projects in future-oriented industries is also demonstrated by its aerospace industry certification. A degree of diversity in the industries served ensures long-term security. “Our experience in the semiconductor industry helps us to tap into new markets, because technical ceramics are becoming increasingly important in other sectors as well.” Against this backdrop, he also sees ULTRASONIC technology as important for the future: “Our capacity in this area will increase, as will our requirements for the level of machining quality.”

Fuchshofer Präzisionstechnik GmbH

Haselbach 100

8552 Eibiswald

Österreich

Fuchshofer Präzisionstechnik