LASERTEC 20 PrecisionTool

Diamond tool machining with up to 3 mm / min and up to 56% lower costs per part compared to eroding

Max. X-axis stroke

8 in.

200 mm

Max. Y-axis stroke

16 in.

400 mm

Max. Z-axis stroke

11 in.

280 mm

Control & software alternatives

SIEMENS

Highlights

NEW: High Speed Mode 3.0 – 210 % faster speed

and 56 % lower cost per part compared to EDM!

- Laser finishing of diamond tools with up to 3.0 mm/min

- Individual edge preparation: < 1 µm sharp edge

- 3, 6, 9, 12, 15 µm defined edge roundness as well as egative chamfersLonger tool life up to factor 2,5 due to laser machining

- 5-axis separation of cutting inserts out of blanks up to 10x faster than conventional wire EDM (machine version PreCut).

Established software features - the easiest switch from eroding to laser processing!

- Industry standard (GTR) as a programming solution allows the import of existing EDM projects

- Minimal training required when switching from eroding to lasers

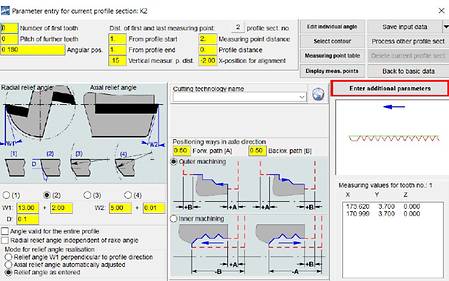

- EndMill software - programming of rotary tools

- TurningTools software - programming of fixed tools

- ChipBreaker Software - programming of chip breakers and negative chamfers

Highly dynamic 5-axis precision machine in the portal design with 5 µm positioning accuracy, compact with a 3.5 m² footprint

- Highly dynamic through linear drives in the X-, Y-, Z-axis with > 2 g

- Integrated swivel rotary table (4th / 5th axis come standard) with torque technology, –10° / +130°

- Precision cooling in all axis

State-of-the-art CNC-control

- Siemens 840D solutionline with Operate 4.7 on CELOS from DMG MORI for simple operation and complete integration into the company organisation

- LASERSOFT software packages for machining shank and HSK tools, ISO and special cutting inserts, chip breakers

Automation solution with integrated linear magazine PH 10 | 100

- Compact and integrated design with a 6 m² footprint

- Handling of cutting discs, shaft tools and tools with HSK-holder (combination of different tool types possible)

- Up to 12 tools ø 200 mm / l = 260 mm or up to 54 tools ø 85 mm / l = 140 mm

Application Examples

Automation

Standard automation and customized solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customized automation solution for flexible manufacturing systems: