Precision and Efficiency in Detail: The CNC Milling Machine Setup

Milling is one of the most important manufacturing processes in modern production. Powerful and precise CNC machines are essential for machining parts with high accuracy and consistent quality. Whether in aviation, mobility, or medical industries – CNC milling enables the production of simple to complex geometries with tolerances in the micrometer range. The process also impresses with its versatility, cost-effectiveness, and high degree of automation.

The continuous development of CNC milling machines has ushered in a new era of technological advancement, allowing productive and quality-focused machining of a wide range of materials – from aluminum and stainless steel to titanium and other hard-to-machine materials. But what lies behind the technology? Which components enable this performance? And how do the different types of CNC milling machines differ? To answer these questions, it is worth taking a detailed look at the structure of this class of machine tools – from the machine bed and axes to the milling spindle, tool holder, and digital control system.

Basic Structure of CNC Milling Machines

The structure of a CNC milling machine follows a modular principle, where mechanical, electrical, and digital components interlock. The basic structure consists of the mechanical design, the drive system with linear and rotary axes, and the electronic control system.

Mechanically, a milling machine comprises the machine bed, guides, milling spindle, tool changer, workpiece clamping table, and in some cases, a pallet changer. These components ensure stability, rigidity, and thermal consistency – all crucial for long-term machining accuracy.

Electronically, the CNC control system, in conjunction with servo or direct drives and sensors, ensures precise movement along the programmed tool paths. The control system also handles safety functions, process monitoring, and integration into digital manufacturing networks. A well-configured program is essential for a successful setup and smooth running of the machine.

Depending on production requirements, CNC milling machines are categorized into several types:

- 3-Axis Vertical Milling Machines: In this standard configuration, machining occurs along the linear X, Y, and Z axes. The spindle is usually positioned vertically above the workpiece, while horizontal 3-axis machines are less common. Vertical milling machines like the NVX series from DMG MORI offer excellent visibility and high precision.

- 4-Axis Milling Machines: These add a rotary axis, typically in the form of an integrated rotary table in horizontal milling machines. The fourth axis allows machining of side or angled surfaces without manual repositioning. A good example is the NHX series, which integrates well into automated production cells with linear pallet systems.

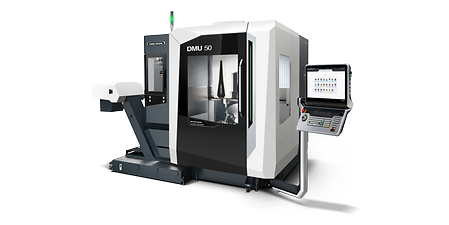

- 5-Axis Machining Centers: The most complex type, these machines feature two additional rotary axes – a tilting and a rotating axis – which may be located in the table or the milling head. For instance, the DMU 50 3rd Generation uses a swivel-rotary table to implement a table-table kinematic system, ideal for lighter workpieces. The DMU 80 P duoBLOCK uses a table-head configuration with a high-load rotary table and a tilting axis in the tool. If both rotary axes are in the head, it’s called a head-head kinematic system. This setup, with the table resting on a stable foundation, is designed for heavy workpieces. DMG MORI’s DMU Gantry series is based on this principle. In all cases, 5-axis milling enables the production of complex freeform surfaces in a single setup.

Compared to CNC turning machines, there is a key difference: in CNC milling, the tool moves over the stationary workpiece, while in CNC turning, the workpiece rotates and the tool remains relatively static.

Key Components in Detail

- Machine Bed: The machine bed is the foundation of every CNC milling machine. It supports all components and contributes significantly to structural rigidity. Made from vibration-damping materials like cast iron, it ensures precision even under high dynamic loads.

- Guides and Axes: Movement in three or five spatial directions is achieved via high-precision linear guides. Axes are driven by servo motors and ball screws or linear direct drives, depending on the application. High-resolution length measuring systems provide feedback on exact positions – a key element for accuracy.

- Milling Spindle: The spindle is the productive heart of the milling machine. It rotates the tool at speeds of over 40,000 rpm or torques exceeding 2,000 Nm, transmitting both torque and cutting force to the workpiece. Cooled spindle bearings and vibration sensors ensure stability even during demanding operations.

- Tool Holder and Tool Changer: The interface between the spindle and the tool is the tool holder – often designed as HSK, CAPTO, SK, or BT taper. It ensures a secure and precise connection. Automatic tool changers increase efficiency by reducing setup times and enabling continuous operation.

- CNC Control System: The CNC control interprets the programmed NC code and translates it into precise machine movements. Systems from Heidenhain, Siemens, Mitsubishi, and Fanuc, as well as the overarching MAPPS platform, offer adaptive feed control, tool monitoring, and digital interfaces. The control system is essential for the safe and efficient execution of complex machining strategies. Integration with CAM software ensures that the program is optimized for each part and cutting condition.

Interaction of Components

Only when all components are perfectly coordinated can a CNC milling machine reach its full potential. This includes mechanical stability, thermal behavior, control technology, and software integration. The quality of a workpiece depends not only on the cutting tool but on the harmonious interaction of the entire machine. A proper setting of each component is essential to ensure the machine is running efficiently and properly.

Digital technologies are also becoming increasingly important: real-time data, adaptive control systems, and predictive maintenance enable stable, cost-effective processes with maximum efficiency and minimal waste – in line with modern manufacturing strategies.

Milling Machines for the Future of Manufacturing

Modern milling machines open up new approaches and pave the way for the future of manufacturing. Especially with 5-axis machines, the focus is increasingly on efficient complete machining of complex components. This includes both the mechanical processing of intricate geometries in a single setup and the integration of additional processes. Technologies such as turning, grinding, gear milling, and measuring can be integrated. Universal machines like these also serve as an ideal foundation for automated and highly economical production. Modern control systems like DMG MORI’s intuitive CELOS X interface ensure seamless integration into increasingly digitalized manufacturing processes. These optimizations also contribute to more resource-efficient and sustainable production.

Conclusion

The structure of a CNC milling machine combines mechanical precision, electronic intelligence, and digital control into a highly efficient overall system. From the machine bed to the spindle and NC control – every component plays a crucial role in the precise and economical machining of complex workpieces. In an era where flexibility, accuracy, and sustainability increasingly determine industrial success, modern CNC milling machines are indispensable. Manufacturers like DMG MORI demonstrate how holistic strategies can drive the transformation toward digital, automated, and green manufacturing – powered by machines that are more than just tools: they are integral to the production of tomorrow.